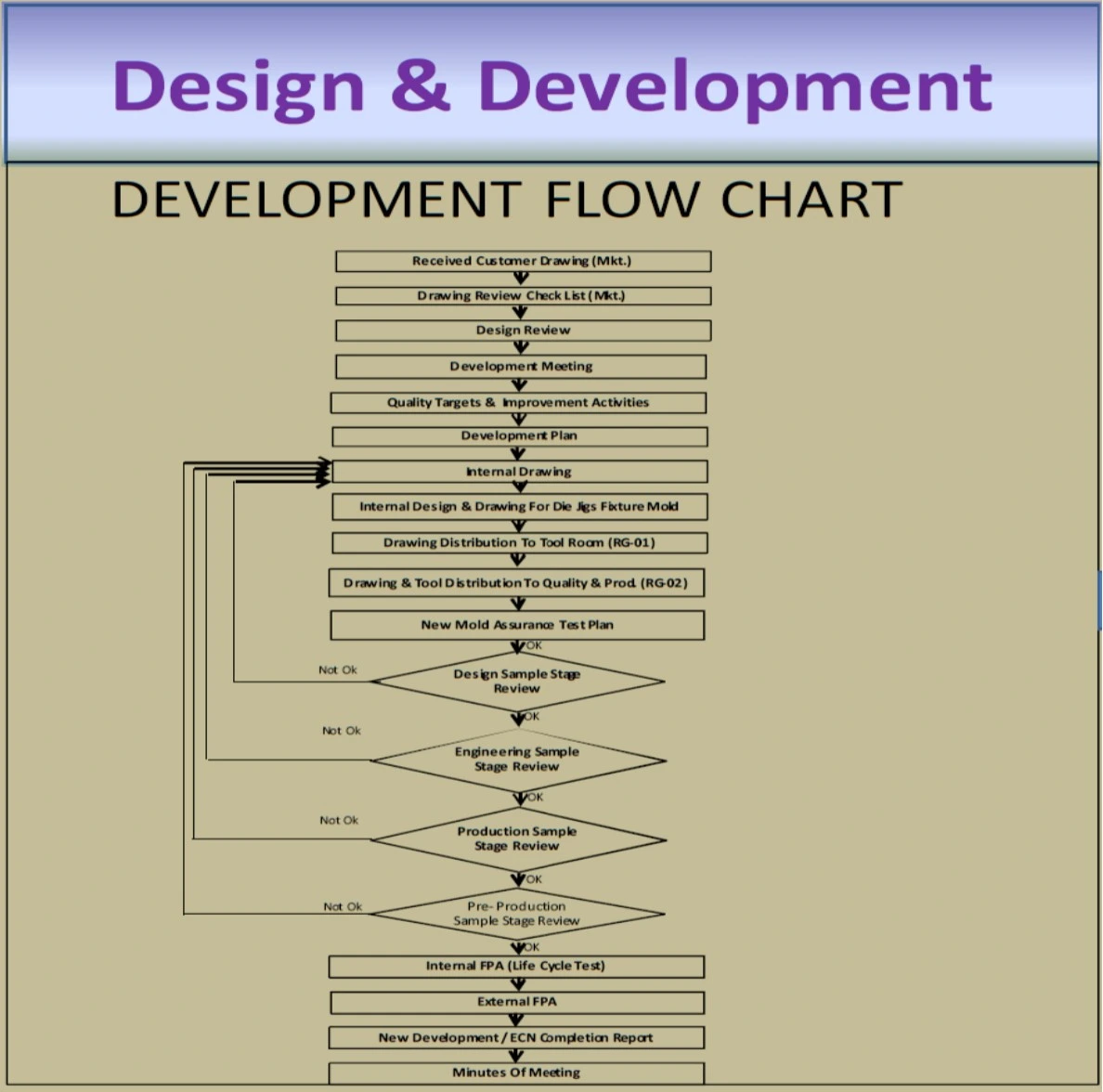

Our inhouse design and development department focuses on product designing, mould designing, prototype designing, printing design and tooling and tooling. We have an inhouse design, development, tooling and testing department located in Greater Noida, NCR.

Our inhouse design and development department independently verifies and develops OEM designs received from customers and converts such designs into deliverable products and solutions by improving the designs, recommending suitable raw materials mix and testing of trial products.

In addition, our inhouse design and development team aims to provide solutions through automation to improve manufacturing efficiency of our existing product lines, reduce production costs and assists our customers by providing design and engineering support. We focus on activities to support our customers including design refinement, generating optional features and testing. We use advanced CAD/CAE software for optimization of products as well as tooling. This enables us to address our consumers’ diverse needs, introduce new and innovative component products in the market, enhance existing products with emerging technologies, and optimize costs across our products through value analysis and value engineering.